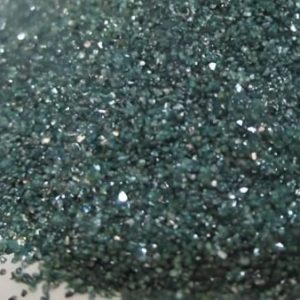

White Fused Alumina (WFA) is another high-quality synthetic abrasive material produced through the fusion of high-purity alumina in an electric arc furnace. It differs from Brown Fused Alumina in that it is made from higher purity raw materials, leading to a white, much purer product with different properties. Here’s a comprehensive overview:

Applications of WFA:

- Abrasives: Grinding and Cutting Tools

- Refractory Materials: High-Temperature Applications, Ceramic Industry

- Blasting Media

- Polishing and Coating

- Water Filtration

Key Differences between White Fused Alumina and Brown Fused Alumina:

Purity: WFA is made from higher purity raw materials, resulting in a higher Al2O3 content and a whiter color.

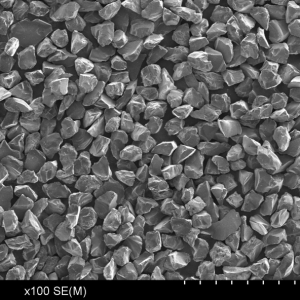

Hardness and Brittleness: WFA is harder and more brittle than BFA, making it suitable for precision applications but not for heavy-duty grinding or operations that require high toughness.

Applications: While both are used in abrasives and refractories, WFA is generally preferred for fine grinding, polishing, and high-precision finishing applications.